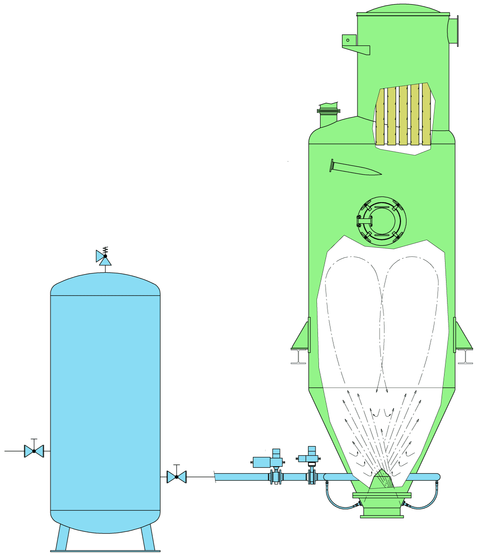

The Air-Mixer is a pneumatic mixer for fast and gentle mixing and homogenizing of bulk solids

It is a discontinuous, pneumatic mixing process for all free flowing bulk solids and bases on the abrupt and complete gyrating of the mixing product by means of gas-jets that are injected at a certain angle into the mixing product.

It is a discontinuous, pneumatic mixing process for all free flowing bulk solids and bases on the abrupt and complete gyrating of the mixing product by means of gas-jets that are injected at a certain angle into the mixing product.

Features:

•Can be used to homogenize contents in silos for emptying them.

•Very short mixing time while maintaining a high mixing quality, even with products with different densities.

•maximum system performance at mixing and conveyor stations in one, up to 2000 tons per day possible

•minimum energy requirements 0.2 - 1 KWh / 1000 kg of powder, 6 - 8 KWh with Granule

•Most gentle treatment of the product, very low abrasion.

•No heat-development

•Very low wear out, even with aggressive products.

•No mechanical moving parts.

•No contamination of the product through gasket-abrasion or lubricants

•Empties completely without build-up of product inside mixer.

•Easy and fast cleaning through gas-cleaning

•Addition of fluids possible.

•Mixing unit in simple Design.

Product:vegetable materials

density:400 Kg/m³

grain size:500 μm

density:400 Kg/m³

grain size:500 μm

Dust-explosion class:II

Mixing unit:2 pieces type II/K

net volume:10 m³

gross volume:18 m³

Diameter:2,2 m

Material:1.4301

net volume:10 m³

gross volume:18 m³

Diameter:2,2 m

Material:1.4301

Filter:2 x 10 m²

Gas storage:8 m³ at 15 bar

Mixing time approximately:6 min.

Gas-consumption:24 m³/1000 Kg

expected deviation: 5%

achieved deviation: 2%

Mixing time approximately:6 min.

Gas-consumption:24 m³/1000 Kg

expected deviation: 5%

achieved deviation: 2%

Product:pellets

Density approximately:700 Kg/m³

Density approximately:700 Kg/m³

grain size:diameter up to 4mm; length up to 4mm

Mixing unit:type IV/K/S

Net volume:34 m³

Gross volume:57 m³

Diameter:3,2 m

Material:1.4301

Mixing time approximately:6 min.

Gas Storage:30 m³ at 24 bar

Gas consumption:27 m³/1000 Kg

expected deviation:2%

achieved deviation:0,58

Net volume:34 m³

Gross volume:57 m³

Diameter:3,2 m

Material:1.4301

Mixing time approximately:6 min.

Gas Storage:30 m³ at 24 bar

Gas consumption:27 m³/1000 Kg

expected deviation:2%

achieved deviation:0,58

Adress:

Seco Anlagentechnik GmbH

In der Mark 28a

63683 Ortenberg-Lissberg

Germany

Contact:

Tel.: +49 6046 7779

Fax: +49 6046451

E-Mail: seco@seco-lissberg.de

Tel.: +49 6046 7779

Fax: +49 6046451

E-Mail: seco@seco-lissberg.de