Task of a bag emptying system is the emptying of bags. This can be done in a variety of automation levels.

Starting with a manual and dust-free emptying in a bagchute to a fully automatic unloading in which only one worker in the forklift sits and brings new pallets and empty bags (which were pressed to bales) drives away, anything is possible.

Our systems are robust and easy to maintain, so we have managed that we do not need a service department until today.

We specialize in difficult products such as Caprolactam, E-PVC, Atex and food plants. But even with products that are easy to empty, such as granules, our systems are a good choice.

Starting with a manual and dust-free emptying in a bagchute to a fully automatic unloading in which only one worker in the forklift sits and brings new pallets and empty bags (which were pressed to bales) drives away, anything is possible.

Our systems are robust and easy to maintain, so we have managed that we do not need a service department until today.

We specialize in difficult products such as Caprolactam, E-PVC, Atex and food plants. But even with products that are easy to empty, such as granules, our systems are a good choice.

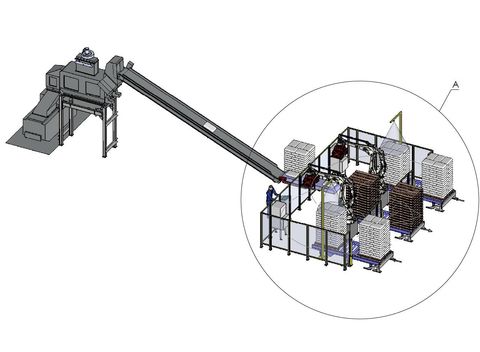

Fully automatic bag emptying plant with robot:

The pallets are placed on a roller conveyor and a robot depalletiert the bags individually on the conveyor belt of the bag emptying machine

The pallets are placed on a roller conveyor and a robot depalletiert the bags individually on the conveyor belt of the bag emptying machine

Subsequent protective screening prevents bag snippets in the product

The empty bags are pressed into bales in a baling press and can be brought by forklift or pallet truck

As an example, an E-PVC system for 400bags / h

Instead of a robot, you can also use a lifting and tilting table. The worker who hangs up the bags only has to pull the bags onto the conveyor belt and not lift them

The simplest variant is just a conveyor belt. Here the worker has to lift the sacks off the pallet and place them on the conveyor.

Sack emptying system for caprolactam (CPL)

Since CPL solidifies in the bag completely, this system is equipped with crushers that break the product so small that it can be processed. There are three different crusher rollers in the system and a protective sieving can be done at the end

Since CPL solidifies in the bag completely, this system is equipped with crushers that break the product so small that it can be processed. There are three different crusher rollers in the system and a protective sieving can be done at the end

Semi-automatic bag emptying system

In this system, the bag Manuel is placed in the machine and cut automatically. The emptying takes over again the worker.

Big advantage of this version is that the worker does not come into contact with the product.

Performance about 150 bags / h

In this system, the bag Manuel is placed in the machine and cut automatically. The emptying takes over again the worker.

Big advantage of this version is that the worker does not come into contact with the product.

Performance about 150 bags / h

Adress:

Seco Anlagentechnik GmbH

In der Mark 28a

63683 Ortenberg-Lissberg

Germany

Contact:

Tel.: +49 6046 7779

Fax: +49 6046451

E-Mail: seco@seco-lissberg.de

Tel.: +49 6046 7779

Fax: +49 6046451

E-Mail: seco@seco-lissberg.de